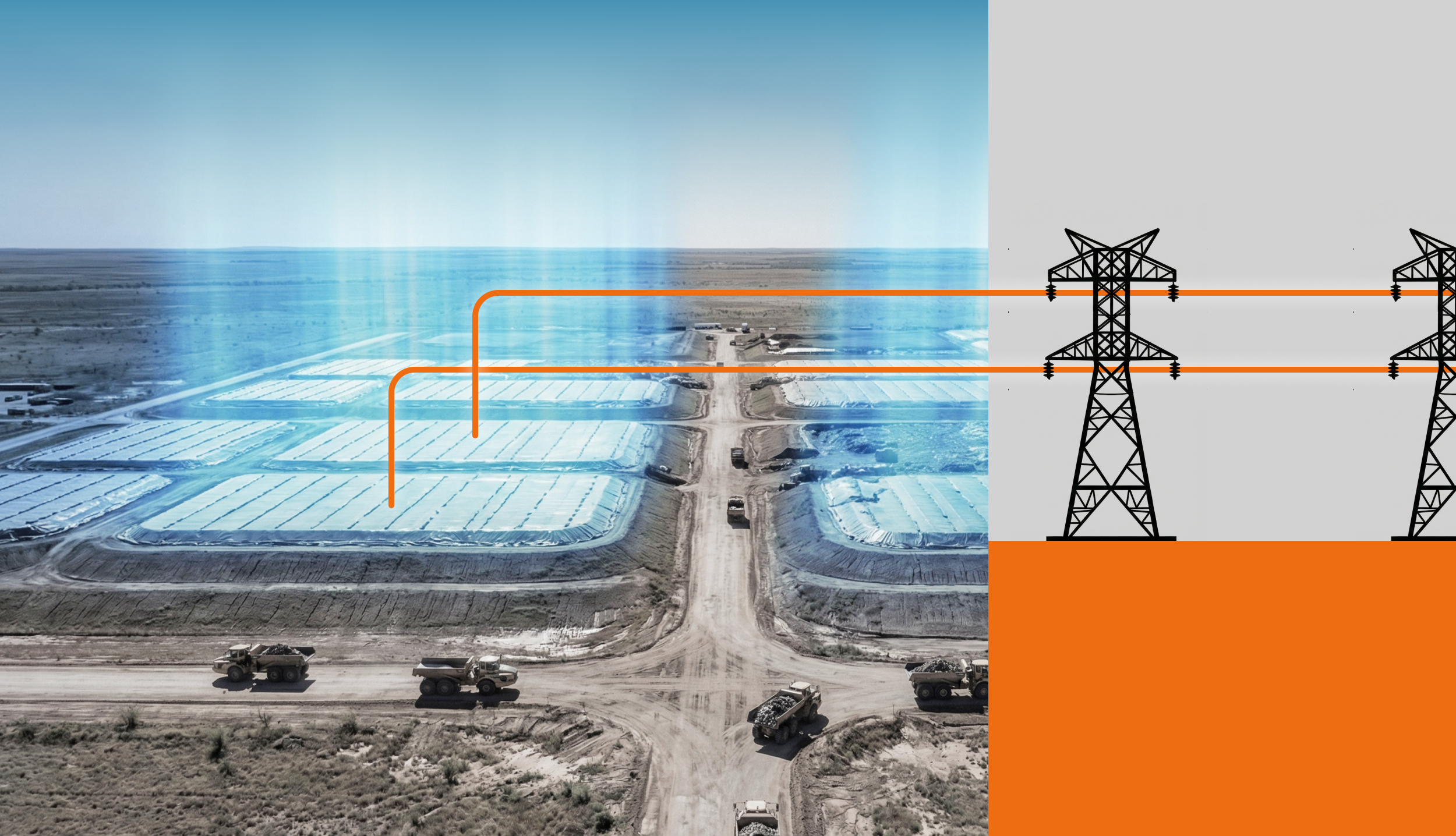

LANDFILLS ARE FUTURE POWER PLANTS

Turning above ground carbon in landfills into baseload power.

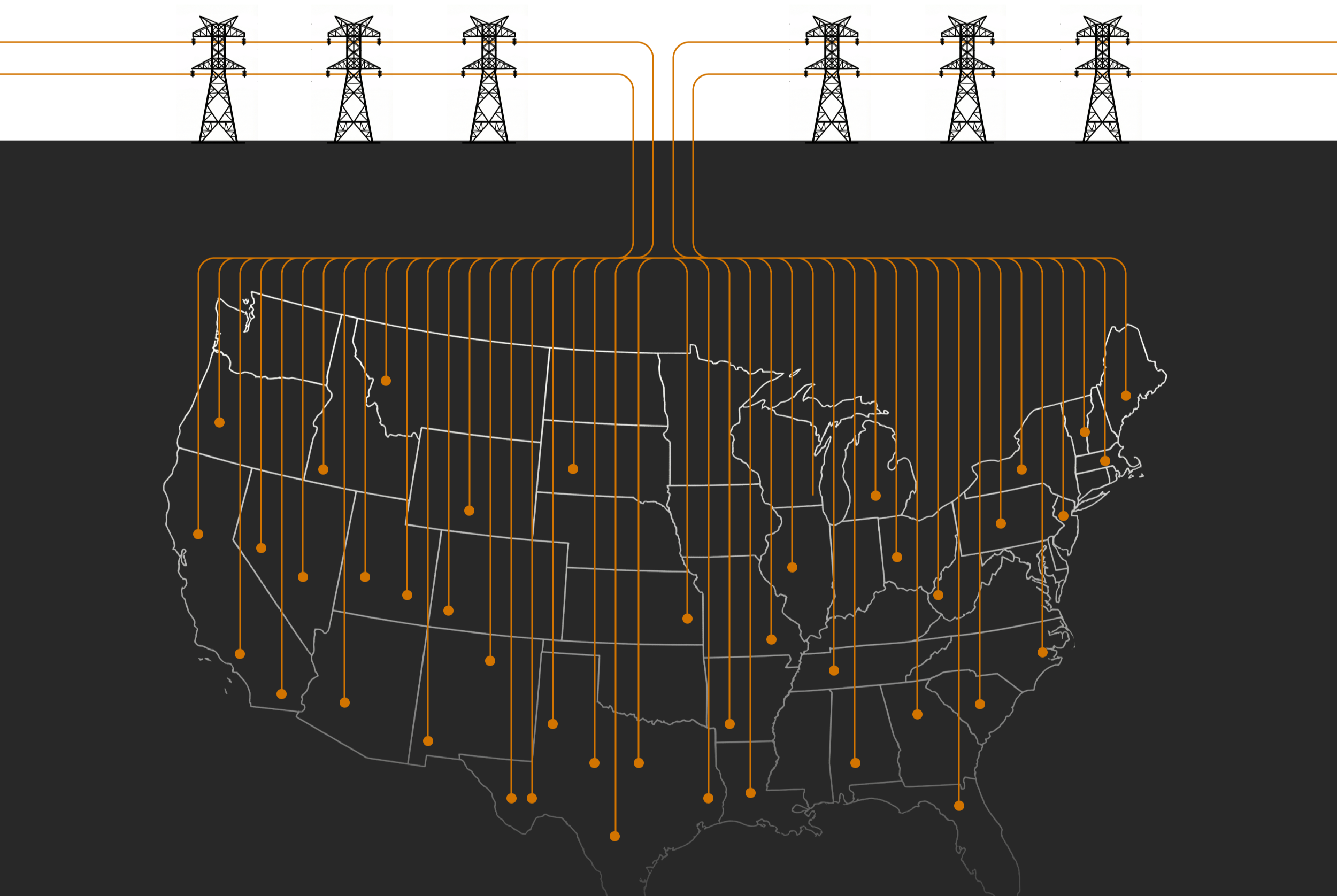

Waste to GigaWatts

Landfills in the US form an ideal energy network. Close to power demand, grid infrastructure adjacent, abundant feedstock supply.

1 Landfill

≈ 25 MWe

4 Landfills

≈ 100 MWe

40 Landfills

≈ 1 GWe

Power That Scales

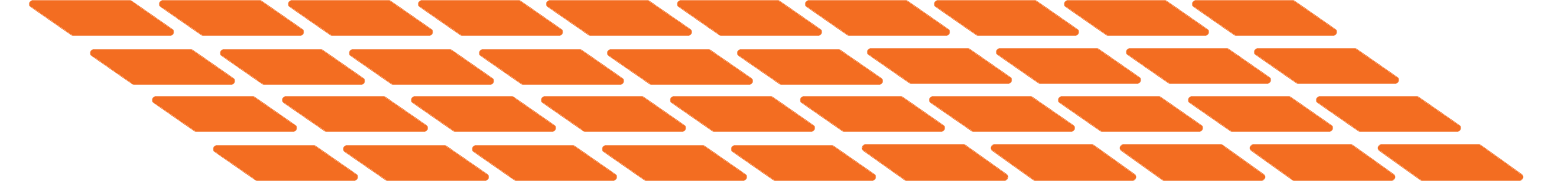

Building the next generation of resilient power infrastructure. Kore’s non-combustion MX-1 reactor converts landfill-bound organic waste into baseload power.

Enabled By Modular, Repeatable Clusters.

Speed to electrons requires replication, not mega Capex projects.

Proven Technology and Process

Operationally proven with SoCalGas in LA, permitted in one of the nation’s toughest air districts.

TURN ON THE LANDFILL

Landfills are one of America’s largest untapped power reserves. Kore Infrastructure switches them on.